OBAYASHI CORPORATION TECHNOLOGY RESEARCH INSTITUTE

The brænch

A collaborative project has been realized between Obayashi Corporation’s Technical Research Institute, which developed a metal 3D printer capable of fabricating carbon steel and stainless steel, and DigitalArchi Inc., which operates a large-scale plastic 3D printer.

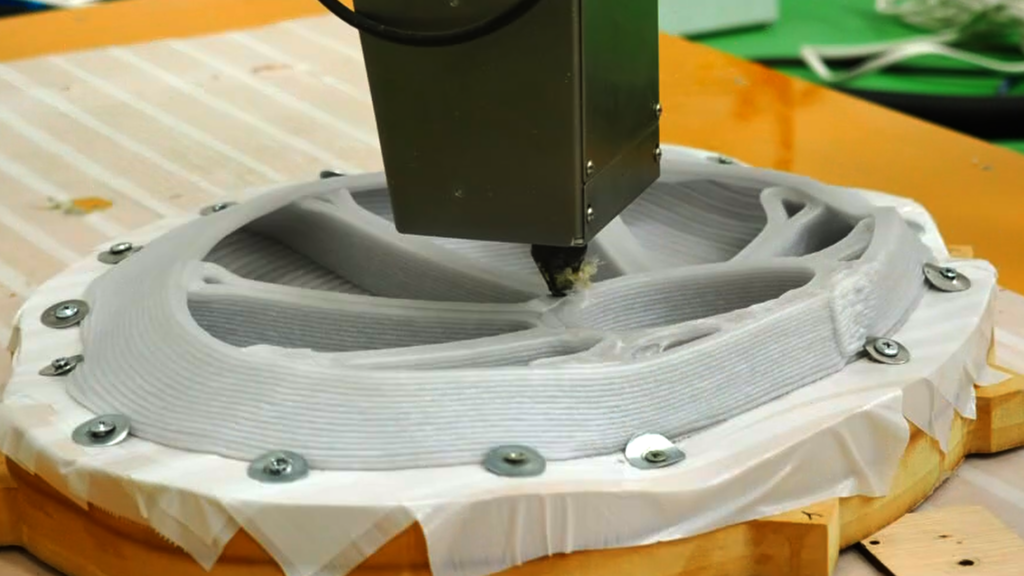

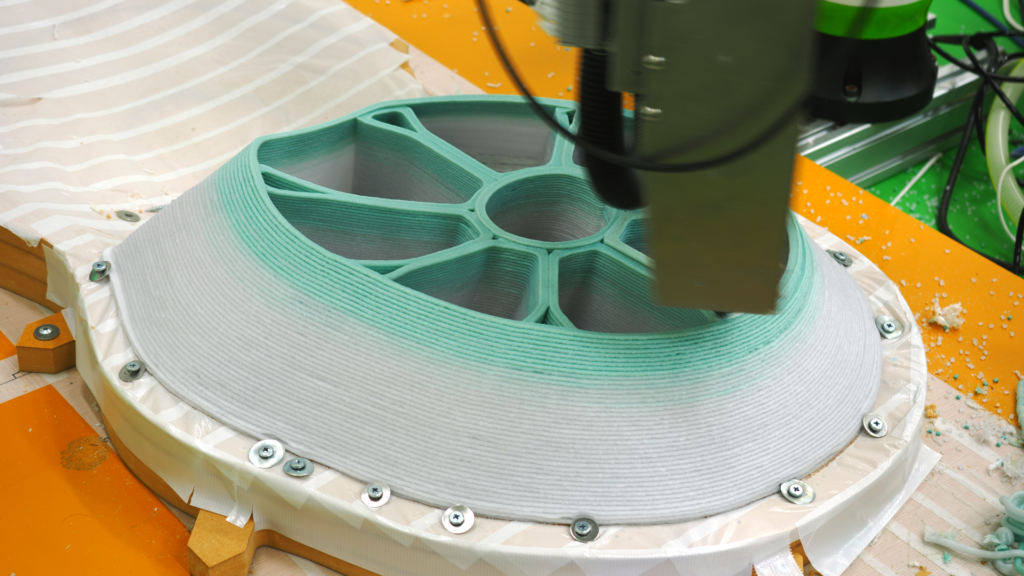

In this project, DigitalArchi was responsible for producing the bench seat and the petal-shaped roof components, using a robot-arm-type large-scale plastic 3D printer for fabrication.

In conventional material-extrusion 3D printing, it is necessary to prepare a flat and smooth bottom surface at the start of printing. However, for large-scale prints and organic shapes, this requirement has significantly constrained design freedom.

In this project, this challenge was addressed by combining the following two technologies:

- Utilization of a CNC-machined three-dimensional base

A three-dimensional base was created by CNC machining to match the printing position, and printing was started on top of it. This eliminated the need to flatten the bottom surface and made it possible for the first layer to adhere directly to complex curved surfaces. - Nonplanar Slicing Incorporating Robot-Arm Head Angle Control

Leveraging multi-axis control capabilities, we developed a proprietary nonplanar slicing method that controls the nozzle angle at each layer. By tilting the nozzle and depositing material along curved surfaces, printing can begin without requiring a smooth, flat starting surface.

By combining these technologies, the conventional assumption that “the first layer must be flat” was removed, enabling printing that starts from organic and three-dimensional shapes. This project serves as one demonstration of a new large-scale 3D printing method that is not constrained by flatness across all layers.

Youtube:The brænch — A Large-Scale 3D-Printed Bench Inspired by Tree Branches

Youtube(Obayashi Corporation):The Brænch | 3D printing with steel

Press release(Obayashi Corporation):Production of a Large-Scale Mock-Up Using a Metal 3D Printer